|

How to add more flow to an edge gate design.

Definition: 1) similar in design to an edge-type gate, but with a non-uniform design in height and width. 2) A gate in which the width is minimally over 2 times the height, and also wider than the runner feeding the gate, while maintaining a uniform flow for the various cross-sectional area. 3) A wide and thin edge gate.

Typically a fan gate is used for cosmetics on a part, and may in fact be confused with a chisel gate design, at times. The fan gate is a variation of the edge gate, and may allow for easier filling of thin wall parts in that it allows for large volume of flow. The down side of using the fan type gate is that there is a large vestige left on the part.

Please note that in review for this article the author found many definition and designs for fan gates, and does recognize that many may disagree with what is shown. In further articles it is hoped to show other variations and their associated names.

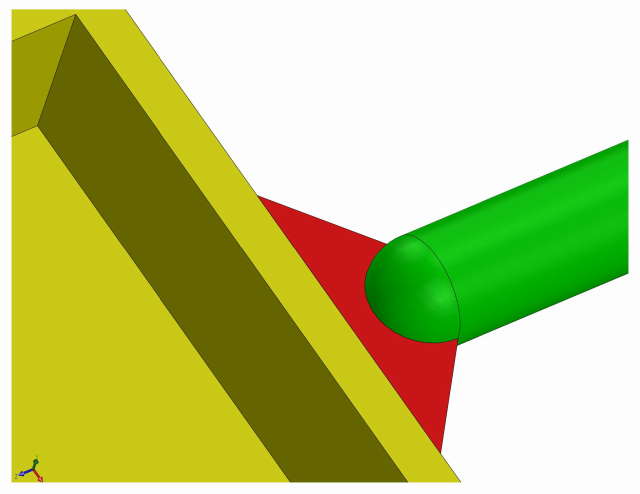

Figure 1

Figure 1 shows both the top view of a minor fan gate and another view, minor in this example is that the width is not as wide as it may need to be.

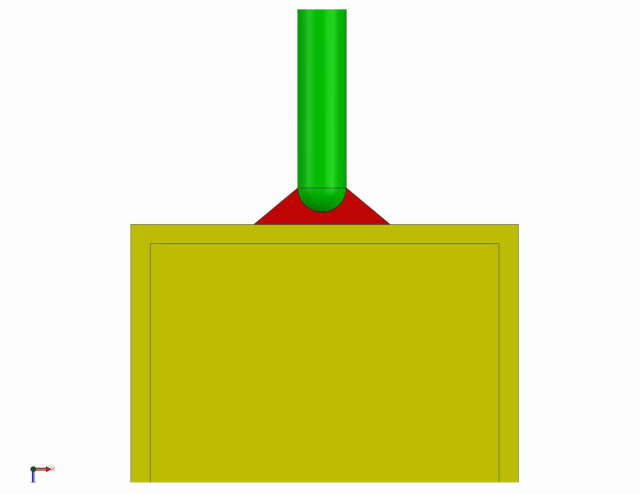

Figure 2

Figure 2 shows the side view of the fan gate. In this example a full round runner is used, but the gate location is such that the Parting line is on the center line of the runner and this area is flat while the bottom side of the gate is tapered so as to aid in the filling of the part in a uniform manner.

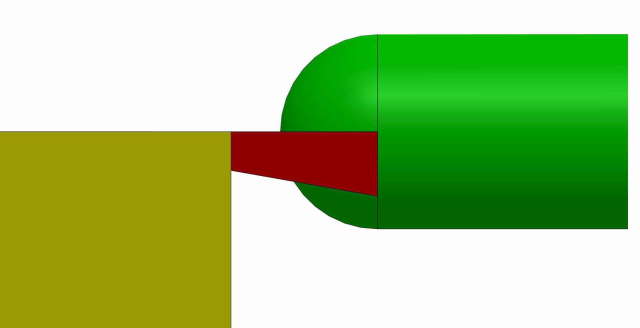

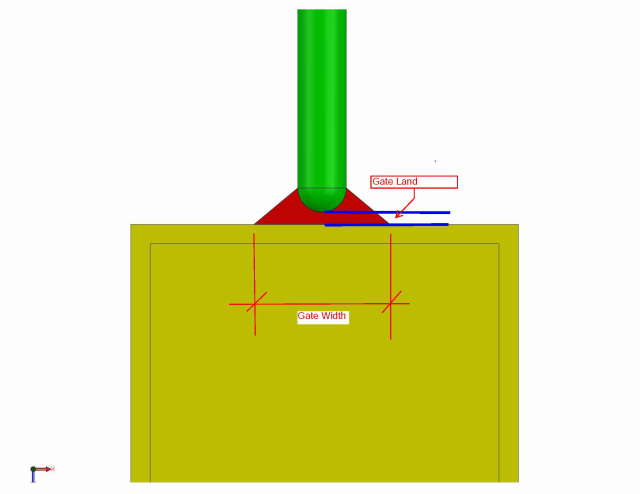

In looking at where are the key components to the gate such as land length, height, and width the following figures should help to explain.

Figure 3

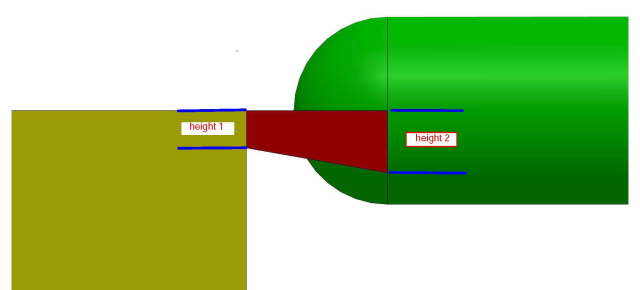

Figure 4

While figure 4 shows two heights #1 and #2 it is important to understand that #1 is based on the wall thickness of the part, and also prior experience and that #2 is based on the height of #1 and the Width of the overall gate plus the diameter of the runner feeding it. The taper which goes to the gate height is to aid in the uniform flow to the part.

In some cases as the width of the gate at the part interface gets wider /longer it may be noticed that the flow is no longer uniform, and tends to be more from the center of flow. In these cases one may now get into tapering the ends of the fan so as to be thicker than at the center of the flow. Understand that Figure 6 shows this and that this interface it at the part wall.

Figure 5

Figure 5 illustrates when a wide fan gate must be used that the center section is thinner than that of the outer. Basically the center section stays the same (as originally calculated) and the outer reaches are increased. The illustration is for reference in what is going on and all must be determined via, calculations and or prior history with a lot of trial and error in some cases. The change as shown is at the gate entrance to the part.

Another point is that the volumetric flow area of the gate should not exceed the volumetric area of runner cross-section.

What are the issues?

The degating of the fan gate or how it is to be degated is, and what mark, vestige is left on the part. While this can be an issue in some parts in others it does not matter and or in some cases it is just machined off, especially when they get large, both in width and height.

Flow pattern can be an issue. What is meant is that in some cases the fan may not be designed correctly and the resulting issue tends to be that the material flow into the part starts out good, using the entire width of the fan but after a bit only the section at the center is contributing flow to the part. This effect may or may not be a concern for the part manufacture. If it is not a concern great, if it is than a simple test is to run multiple colors through the machine and observe the changeover effect within the part and at the sectioning of the gate and runner. This all goes back to fountain flow in that the latest and hottest material is flowing through the center, and then distributing out.

Note* that by sectioning the gate and runner what one does is to cut the area into slices across the flow direction and observe the rings / flow channel. This is much like sawing a tree and observing the growth rings.

SLSilvey

31072015.01

Visit our website

|