|

|

|

|

Prevention Through Design

Debby Shewitz, CSP, PHA - Cleveland, OH

In his first public announcement of his priorities (and just 5 days after being sworn in as the new Assistant Secretary of Labor for OSHA), Dr. David Michaels outlined for the audience at the NIOSH Green Jobs: Making Green Jobs Safe Workshop his 6 areas of focus going forward. They are:

- chemicals management (likely mirroring the the EU legislative approach

- Standards rulemaking,

- management system type processes,

- focused national emphasis programs

- worker voice, and

- prevention through design.

The last focus area, Prevention Through Design (PtD), is not one that safety professionals have heard much about from OSHA before now Those who work in industries covered by OSHA's Process Safety Management of Highly Hazardous Chemicals (PSM) Standard are already using PtD techniques. The PSM Standard requires that any covered process (one that uses certain listed chemicals in quantities above specified thresholds) must undergo a hazard analysis before it is started up if the process is new or if it goes through significant changes. In addition, there must be a pre-startup safety review to make sure that construction and equipment match the design specifications and that safety, operating, maintenance, and emergency procedures are in place and are adequate. But aside from these limited requirements of the PSM Standard, there are no regulatory requirements for conducting safety reviews of projects, and there are no consensus standards in the US to guide a standardized approach to such reviews.

There is certainly no need to convince safety professionals that conducting this sort of hazard analysis is a good thing to do for all sorts of new or changed operations, not just those covered by the PSM Standard. And it is pretty much stating the obvious to say that the ideal place to identify and eliminate (or at least minimize) hazards and risks is early in the design/redesign phase, rather than after they're already built into the system. In fact, many organizations with a strong management systems approach to environmental, health and safety (EHS) already include procedures to ensure that EHS considerations are formally included in project reviews.

Other countries are further ahead in formalizing this approach. Starting in 1994, the United Kingdom began requiring construction companies, project owners, and architects to address safety and health during the design phase of projects. Australia developed the Australian National OHS Strategy 2002-2012, which set "eliminating hazards at the design stage" as one of five national priorities. As a result, the Australian Safety and Compensation Council (ASCC) developed the Safe Design National Strategy and Action Plans for Australia encompassing a wide range of design areas including buildings and structures, work environments, materials, machinery and equipment. But the US is moving to catch up. Since 2007, NIOSH has been leading a nationwide initiative on PtD, in partnership with the American Industrial Hygiene Association (AIHA), ASSE, the Center to Protect Workers' Rights, Kaiser Permanente, Liberty Mutual, the National Safety Council (NSC), OSHA, ORC Worldwide, and the Regenstrief Center for Healthcare Engineering. The following is a summary the activities under this initiative, and the resources available to businesses that are already using EHS design phase reviews (or wish to start doing so). The National Initiative According to the NIOSH website, "the mission of the Prevention through Design National Initiative is to prevent or reduce occupational injuries, illnesses, and fatalities through the inclusion of prevention considerations in all designs that impact workers. The mission can be achieved by:

- Eliminating hazards and controlling risks to workers to an acceptable level "at the source" or as early as possible in the life cycle of items or workplaces.

- Including design, redesign and retrofit of new and existing work premises, structures, tools, facilities, equipment, machinery, products, substances, work processes and the organization of work.

- Enhancing the work environment through the inclusion of prevention methods in all designs that impact workers and others on the premises."

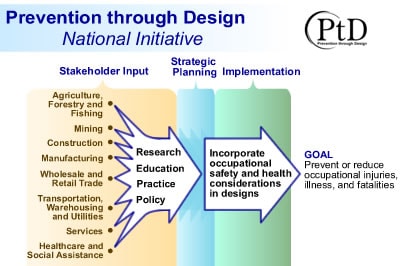

The NIOSH PtD Plan for the National Initiative for achieving this mission is grouped both by industry sectors and by four functional areas: Research, Education, Practice, and Policy, as shown in the following graphic:

The topic of Small Business was added to the functional areas as an additional focus for goal development, to address the unique challenges of applying PtD methods in small business environments. Each of the 4 functional areas, as well as the small business focus area, is supported by a broad strategic goal defined as follows:

- Research: Research will establish the value of adopted PtD interventions, address existing design-related challenges, and suggest areas for future research. Research focuses on design factors that effectively reduce occupational morbidity, mortality and injury; metrics that assess the impact of these design factors; methods to drive the adoption of effective designs; and economic and business issues including financial analysis of the impact of PtD on the business process.

- Education: Designers, engineers, machinery and equipment manufacturers, health and safety professionals, business leaders, and workers will understand PtD methods and apply their knowledge and skills to the design of facilities, processes, equipment, tools, and organization of work. Education focuses on motivating and equipping professional communities to continually increase their knowledge of design features that have a positive impact on worker safety and health. Acquisition of PtD knowledge and skills will occur through enhanced design and engineering curricula as well as through improved professional accreditation programs that value PtD issues and include them in their competency assessments. Making business leaders aware of the potential for increasing company profitability by incorporating PtD methods in their systems and processes is also an important component of the Education goal. Further, some engineering educators are now advocating revision of curricula, so the time for incorporating PtD is potentially at hand.

- Practice: Stakeholders will access, share, and apply successful PtD practices. Practice focuses on identifying and sharing successful procedures, processes, equipment, tools and results through on-line databases and other media. Practice also includes demonstrating the value of including workers' health and safety in design decisions and exploring links with the movements toward green and sustainable design. For worker health and safety, sustainable design enhances indoor environmental quality; and optimizes operational and maintenance practices.

- Policy: Business leaders, labor, academics, government entities, and standard-developing and setting organizations will endorse a culture that includes PtD principles in all designs affecting workers. Policy focuses on creating demand for safe designs for workers and incorporating these safety and health considerations into guidance, regulations, recommendations, operating procedures, and standards.

- Small Business:Small businesses will have access to PtD resources that are designed for or adapted to the small business environment. These goals explore methods for tailoring successful PtD practices and programs to small businesses and drive the adoption of such practices and programs.

Each of these broad goals is supported by a number of intermediate goals (action items). NIOSH is now in the implementation phase of the initiative, and the status of each individual action item is displayed online at http://www.cdc.gov/niosh/programs/PtDesign/goals/. According to the Initiative's timeline, the implementation phase is anticipated to run through 2011. At that time, they hope to be entering a phase of Performance and Sustainability.

Related Activities

ASSE

In parallel with the NIOSH National Initiative activities, ASSE has recently issued Technical Report ASSE TR Z790.001-2009 Prevention through Design - Guidelines for Addressing Occupational Risks in Design and Redesign Processes. This technical report provides detailed guidance on implementation of PtD including:

- Roles and Responsibilities - as with any safety and health activities, primary responsibility lies with senior management

- Hazard Analysis - standard techniques such as Hazard and Operability (HAZOP), Failure Mode Effect Analysis (FMEA), Fault Tree Analysis, What-If studies, etc.

- Risk Assessment - review of matrices to use for quantifying/ranking risk

- Hierarchy of Controls - eliminating/reducing the hazard, engineering controls, administrative controls, PPE, etc.

National Safety Council

The National Safety Council's Business and Industry Division established the Institute for Safety Through Design in 1995, with the vision that:

"Safety, health and environmental considerations are integrated into the design and development of systems meant for human use."

One of the Institute's key focuses is to "affect the content of engineering curricula, so that engineers entering the work force have a knowledge of the principles of designing that includes considerations of safety, health and the environment." Towards this end, the Institute has a joint venture with the State of Utah and the University of Utah to develop undergraduate safety and ergonomics related mechanical engineering course materials. The intention is that these materials will be used not for a separate course on safety, but instead will be incorporated into existing problem sets, homework and lab assignments. Modules are now available for faculty use.

Additional Resources

If Process Through Design is not a topic you are familiar with, this is a good time to start learning more, in expectation of OSHA's new emphasis. A wealth of additional guidance on implementation of PtD is readily available. The NIOSH website, http://www.cdc.gov/niosh/topics/ptd/, contains links to newsletters, journal articles, and other organizations (both US based and international) involved in PtD activities.

Debby Shewitz, CSP, PHA is the principal of Shewitz Consulting, LLC, Cleveland, OH, a teaming partner with STC. She has over 25 years of professional experience in EHS management, almost 20 of which were spent in various safety and environmental management positions in the pharmaceutical and chemical manufacturing industries. She has particular expertise in chemical management and process safety, hazardous waste identification and management, air quality management, and general safety issues. Her consulting practice now focuses on EHS auditing and on implementing new EHS programs for start-up and expanding businesses. Debby has been a member of the ASSE Consultants' Practice Specialty advisory board since 2003, and is currently serving as the organization's newsletter editor. For more information about PtD, Debby can be reached at (216)862-5077 or by email: dshewitz@ix.netcom.com

|

|

|