|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sputtering Start for Flat Materials

From A*STAR Research,

April 15, 2015:

"Researchers at the A*STAR Institute of Materials Research and Engineering have now demonstrated a technique for creating a single atomic layer of molybdenum disulfide - a two-dimensional semiconductor.

Molybdenum disulfide belongs to a family of materials called transition-metal dichalcogenides. They have two chalcogenide atoms (such as sulfur, selenium or tellurium) for every transition-metal atom (molybdenum and tungsten are examples). These materials and their wide range of electrical properties provide an excellent platform material system for versatile electronics. But creating high-quality material over areas large enough for industrial-scale production is difficult."

Image: A*STAR Research Institute of Materials Research and Engineering

|

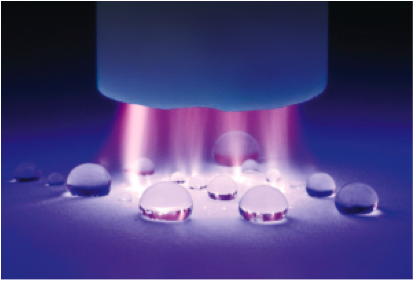

Creating Bare, Two-Metal Particles Provides Insights into Potential Substitutes for Costly Platinum in Fuel Cell Catalysts

From Pacific Northwest National Laboratory, April 2015:

"Platinum's scarcity hinders widespread use of fuel cells, which provide power efficiently and without pollutants. Replacing some or all of this rare and expensive metal with common metals in a reactive, highly tunable nanoparticle form may expand fuel cell use. At Pacific Northwest National Laboratory, scientists made such metal nanoparticles with a new gas-based technique and ion soft landing. As an added benefit, the particles are bare, without a capping layer that coats their surfaces and reduces their reactivity.

The team created the nanoparticles using magnetron sputtering and gas aggregation. They placed them on a surface using ion soft landing techniques devised at PNNL. The result is a layer of bare nanoparticles made from two different metals that is free of capping layers, residual reactants, and solvent molecules that are unavoidable with particles synthesized in solution."

Image: Pacific Northwest National Laboratory/ artwork by Cortland Johnson

|

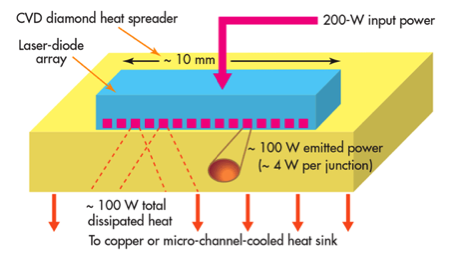

Applications Abound for Synthetic-Diamond Semiconductor Substrates

From Electronic Design, April 2015,

by Bruce Bollinger and Thomas Obeloer, Element Six Technologies:

"Thermal management in semiconductor applications often makes it tough to optimize performance. Synthetic chemical-vapor-deposition (CVD) diamond helps overcome those limitations by significantly lowering gate junction temperatures, thus enhancing power densities and efficiencies as well as extending lifetimes. As technology and economic drivers push systems to higher frequencies, higher voltages, and higher ambient operating temperatures, synthetic diamond heat spreaders and gallium-nitride (GaN)-on-diamond wafers will see increased use in thermal-management schemes for high-power semiconductor devices.

Synthetic CVD diamond's room-temperature thermal conductivity runs as high as 2000 W/mK, five times that of copper and 10 times that of aluminum nitride. Further, because diamond transports heat equally well in all three dimensions, it can act as an excellent heat spreader. Both metallized diamond heat spreaders and GaN-on-diamond wafers have been shown to drastically lower thermal resistance and, in turn, the gate junction temperature of semiconductor devices, leading to higher power densities."

|

Surface Engineering in Medical Technology: From DLC to Plasma and Beyond

From Medical Design Briefs, April 1, 2015, by Lars Gerding (Helix Medical):

"New materials and technological advances continue to proliferate the medtech industry at a rapid rate, and suppliers strive to offer innovative solutions to meet the demands of increasingly complex components and devices. A wide range of specialized materials are used today, and many of those materials are suitable for the intended finished use only after the application of a customized surface treatment. These treatments can result in reduced friction, improvement of haptic properties, the introduction of chemical functionalities, and improved medium resistance of the materials. To meet this growing demand, the supplier can utilize traditional coating methods, like wet chemicals, and state-of-the-art methods, such as plasma treatments, in order to alter the surface properties of medical components."

Image: Medical Design Briefs

|

Surface-Modified Nanoparticles Endow Coatings with Combined Properties

From Leibniz Institute for New Materials (INM), March 26, 2015:

"Fabricators and processors alike demand consistently high quality for their intermediate and final products. The properties of these goods usually also have to meet specific requirements. Particularly the surfaces of workpieces or moldings are expected to exhibit several different functions at one and the same time, depending on the industry. Robustness, unchanging appearance, mar resistance, impact resistance or UV stability may be required, for instance. The INM - Leibniz Institute for New Materials uses nanoparticles as design element for such multifunctional coatings. These nanoparticles are specifically adapted to the particular application by Small Molecule Surface Modification (SMSM)."

Image: Leibniz Institute for New Materials

|

Better Electrodes for Neurochemistry

From Chemical and Engineering News, March 30, 2015 by Celia Henry Arnaud:

"For decades, neurochemists have used carbon fiber microelectrodes to measure electrical activity or detect neurotransmitters and other chemicals among nerve cells. The electrodes have worked well, but they have their drawbacks. They typically achieve spatial resolution of only tens of micrometers. They get fouled easily. They come in limited shapes and sizes. And researchers make the electrodes individually, so no two are identical."

Source: Chemical and Engineering News, cen.acs.org/ (third article in the series)

Image: Chemical and Engineering News/Cheng Yang

|

|

From SPIE Newsroom, April 21, 2015, by Guy Le Lay, et al:

"Silicene and germanene, graphene's cousins, i.e., novel silicon and germanium 2D allotropes with a honeycomb structure, offer tantalizing prospects to achieve the ultimate in miniaturization with direct compatibility with silicon technology.

In theory, freestanding silicene and germanene have a lightly buckled honeycomb structure with mixed sp2/sp3 hybridization (unlike graphene, which is purely sp2 hybridized and flat), but they do not exist in nature. Graphene has a parent crystal (graphite), but this is not the case for silicene or germanene. Consequently, researchers synthesize them in situ under ultra-high-vacuum conditions by silicon or germanium sublimation onto, typically, silver (111) or gold (111) single-crystal surfaces (111 describes which surface). In proper growth conditions, at rather low growth temperatures (about 220įC), epitaxial monolayer sheets are formed on these substrates with modified corrugation compared to the theoretically predicted freestanding materials, favored by the low stiffness of these 2D sheets."

|

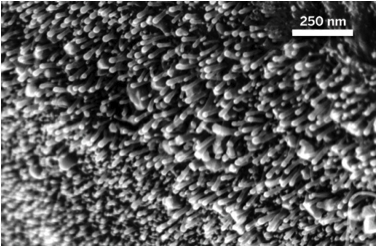

Gecko Skin Could be the Shape of Things to Come

From the University of the Sunshine Coast (Australia), June 10, 2015, by Jane Cameron:

Gregory S. Watson, David W. Green, Lin Schwarzkopf, Xin Li, Bronwen W. Cribb,

Sverre Myhra, Jolanta A. Watson: A gecko

skin micro/nano structure - A low adhesion, superhydrophobic, anti-wetting, self-cleaning, biocompatible, antibacterial surface. Acta Biomaterialia, 21, 109-122, 2015. DOI:10.1016/j.actbio.2015.03.007

Gregory S. Watson, Bronwen W. Cribb, Lin Schwarzkopf, Jolanta A. Watson: Contaminant adhesion (aerial/ground biofouling) on the skin of a gecko. J. R. Soc. Interface 12, 20150318, 2015. DOI: 10.1098/rsif.2015.0318.

Gregory S. Watson, Lin Schwarzkopf, Bronwen W. Cribb, Sverre Myhra, Marty Gellender, Jolanta A. Watson: Removal mechanisms of dew via self-propulsion off the gecko skin. J. R. Soc. Interface 12, 20141396, 2015; DOI: 10.1098/rsif.2014.1396.

"A team of scientists, led by Dr. Greg Watson, now based at the University of the Sunshine Coast, and the University of Hong Kong's Dr. David Green, examined the skin of the box-patterned gecko of Western Queensland. Their discovery of how the gecko's skin expels water by making droplets clump together then self-launch like popcorn from the surface, received worldwide attention in April with media coverage including National Geographic.

By automatically keeping itself dry, researchers assume the gecko avoids potentially harmful microbes and fungi breeding on its skin. They found that not only does the gecko skin repel liquids, it self-cleans, resists dirt and pollen and kills bacteria on contact but provides a suitable surface for the growth of human stem cells."

Image: University of the Sunshine Coast

|

"Holey" Graphene for Energy Storage

From University of California - San Diego, April 21, 2015, by Liezel Labios:

"Engineers at the University of California, San Diego have discovered a method to increase the amount of electric charge that can be stored in graphene, a two-dimensional form of carbon. The research may provide a better understanding of how to improve the energy storage ability of capacitors for potential applications in cars, wind turbines, and solar power.

Researchers at the Jacobs School of Engineering at UC San Diego introduced more charge into a capacitor electrode using graphene as a model material for their tests. The principle is that increased charge leads to increased capacitance, which translates to increased energy storage."

Image: University of California - San Diego,

|

UNL Wins $9.6 Million NSF Grant for Nanotech Research Center

From University of Nebraska - Lincoln, April 20, 2015, by Gillian Klucas:

"The University of Nebraska-Lincoln has earned a $9.6 million grant from the National Science Foundation to support its Materials Research Science and Engineering Center and its nanotechnology research through 2020. Through this multidisciplinary center, UNL physicists, chemists and engineers collaborate to study nanostructures and materials that could lead to more energy-efficient electronic devices.

The center receives a new name with this latest funding -- Polarization and Spin Phenomena in Nanoferroic Structures, or P-SPINS -- to reflect its expanding research focus on nanoferroic materials, which may one day transform electronics and computing technologies."

Image: University of Nebraska - Lincoln

|

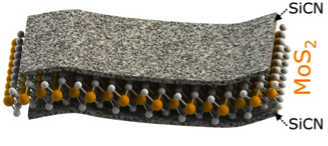

Engineer Improves Rechargeable Batteries with MoS2

Nano 'Sandwich'

From Kansas State University,

April 16, 2015, by Jennifer Tidball:

"Researchers at Kansas State University are improving rechargeable lithium-ion batteries. The team has focused on the lithium cycling of molybdenum disulfide, or MoS2, sheets, which is described as a "sandwich" of one molybdenum atom between two sulfur atoms. The team has found that silicon carbonitride-wrapped molybdenum disulfide sheets show improved stability as a battery electrode with little capacity fading.

Researchers observed that molybdenum disulfide sheets store more than twice as much lithium - or charge - than bulk molybdenum disulfide reported in previous studies. The researchers also found that the high lithium capacity of these sheets does not last long and drops after five charging cycles."

Source: Kansas State University, www.k-state.edu/media/newsreleases/

Image: Kansas State University

|

Multifunctional Materials Able to Respond to Thermal Stimuli and Change Color

From From Nanowerk, April 10, 2015:

"Research conducted at the Institute of Molecular Science (ICMol) of the University of Valencia has made it possible to generate multifunctional materials with different capacities such as responding to thermal stimuli, changing color, being magnetic and presenting movement at the microscale as a result of a variation in their molecular structure.

This study presents what researchers call breathing materials "because of the movement of the crystals, resembling an accordion opening and closing."

Image: University of Valencia

|

3D-Printed Optic Breakthroughs

From R&D Magazine, April 16, 2015 by Tim Studt:

"Just a few years ago, many researchers working in alternative manufacturing methods believed the basic layering technologies integral to 3D printing limited the capability of this technique to build quality optical devices and lenses. But, as rapidly evolving as these techniques are, and as broad ranging as the applications it's infiltrating, this limitation has been surmounted by a number of research groups around the world."

Researchers at LUXeCel Group BV in Goes, The Netherlands, recently added a transparent 3D digital printing service-with its Printoptical process-to its online business-to-business 3D-printing services. Their technology is able to create smooth prints, and is suitable for products that demand the highest standards in transparency-it can produce parts with up to 99.4% optical transparency."

|

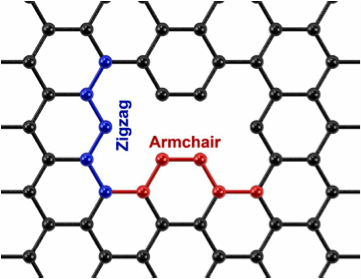

Graphene and Organic Composites in Electronics

From Graphene Flagship,

April 8, 2015,

by Francis Sedgemore:

"Chemists from Europe's Graphene Flagship review the potential for graphene-organic composite materials in electronics. The researchers show how organic semiconductors can be used to better process graphene, and to tune its properties for particular applications. The Graphene Flagship is an international consortium of academic and industrial partners, part-funded by the European Commission, which focuses on the development of graphene and related 2D materials.

The review looks at a number of commercial polymers, the mechanical and electrical properties of which could be improved with the addition of graphene. The authors also consider graphene as a substrate for biomedical applications, and the use of organic semiconductors to open up an electronic band gap in graphene. The absence of a band gap in the pure form of this highly conductive material is a major issue hindering its exploitation in electronics."

Image: Vincenzo Palermo / CNR-ISOF

|

Moving the Goalposts for Organic Photovoltaics - When will Commercialization Come?

From North America Clean Energy, March/April 2015, by Jim Montgomery:

"Organic photovoltaics (OPV) has continued to draw the focus of much research as an alternative solar technology, because of the allure of its core attributes: it's lightweight, flexible, inexpensive, highly tunable, and potentially disposable. Yet, OPV researchers have spent the better part of a decade struggling to translate these competitive promises into something that could be commercially successful.

Surveying the OPV landscape today, we still see a sector striving to translate early lab-scale results into real-world products. However, there are some encouraging signs that the technology is moving closer to commercial readiness."

|

|

|

|

|

Upcoming Conferences of Interest

|

|

The 13th International Symposium on Sputtering and Plasma Processes

July 8-10, 2015

Kyoto Research Park, Kyoto, Japan

The 13th International Symposium on Sputtering and Plasma Processes (ISSP2015) been held biennially and has gathered 135+ presentations and 210+ attendees. The topics of this symposium include: fundamentals of sputtering and plasma processes, sputtering processes, plasma processes, plasma induced process technologies, thin films, micro- and nano-technologies, applications, and others. The program will consist of invited, contributed talks and poster presentations. To encourage young scientists' contributions, poster awards will be given to three outstanding poster presentations.

Contact: ISSP 2015 Office, sec@issp2015.org

Visit the Web Site: issp2015.org

| |

|

|

SEMICON West 2015

July 14-16, 2015

Moscone Center, San Francisco.

Connect to the latest in microelectronics R&D, design, manufacturing, advanced materials, and processes. Attend keynotes, the session on CMP technical and market trends, and 65 hours of technical programs.

Engage with 650+ exhibitors, people, products, and companies driving microelectronics innovation. www.semiconwest.org.

| |

|

|

SPIE Optics + Photonics

San Diego Convention Center

San Diego, CA

August 17-21, 2015

SPIE Optics + Photonics 2015 is the largest international, multidisciplinary optical sciences and technology meeting in North America. The meeting where the latest research in optical engineering and applications, sustainable energy, nanotechnology, organic photonics, and astronomical instrumentation is presented.

Registration Prices Increase July 24, 2015

Visit SPIE and Register: http://spie.org/optics-photonics.xml | |

|

|

The 10th Asian-European International Conference on Plasma Surface Engineering

AEPSE 2015/span>

September 20-24, 2015

Ramada Plaza Jeju Hotel, Jeju Island, Korea

The 10th Anniversary Asian-European International Conference on Plasma Surface Engineering (AEPSE2015) will be held from September 20 to September 24, 2015, in Jeju, Republic of Korea. The AEPSE conference has attracted growing interest as a global open forum for contributing to scientific and industrial progress in applied plasma science and engineering fields.

- Early Bird Registration Deadline - Jul 31, 2015

- Manuscript Submission Deadline - Oct 30, 2015

Learn More at: www.aepse2015.org | |

|

|

AVS 62nd International Symposium and Exhibition

San Jose Convention Center

San Jose, CA

October 18-23, 2015

The AVS 62nd International Symposium and Exhibition scheduled for October 18-23, 2015, in San Jose, California will address cutting-edge issues associated with materials, processing, and interfaces in both the research and manufacturing communities. The weeklong Symposium fosters a multidisciplinary environment that cuts across traditional boundaries between disciplines, featuring papers from AVS technical divisions, technology groups, and focus topics on emerging technologies. The equipment exhibition is one of the largest in the world and provides an excellent opportunity to view the latest products and services offered by over 200 participating companies. More than 2,000 scientists and engineers gather from around the world to attend.

Learn More at: www.avs.org/symposium | |

|

|

AIMCAL Web Coating & Handling Conference

Naples Grande Beach Resort

Naples, Florida

October 25-28, 2015

AIMCAL and SPE have once again joined forces to deliver a standard in technical education and networking, and bring attendees unsurpassed opportunities. SPE‚€™s FlexPackCon will join the 2015 AIMCAL Web Coating and Handling Conference and will include FlexPackCon‚€™s strong focus on flexible packaging materials, processes and new technology combined with AIMCAL‚€™s technology focus on web coating and handling.

For more information, visit: www.aimcal.org/events/web-coating-handling-conference-usa/2015/conference/overview.aspx | |

|

|

9th Symposium on Vacuum-Based Science and Technology

Kolobrzeg, Poland

November, 17-19, 2015

The 9th Symposium on Vacuum based Science and Technology is organized by the Faculty of Technology and Education, Koszalin University of Technology, and the Clausius Tower Society under auspices of the Polish Vacuum Society and the German Vacuum Society and in collaboration with the BalticNet PlasmaTec and the Society of Vacuum Coaters.

The mission of the Symposium is to provide a forum for presentation and exchange of expertise and research results in the field of vacuum and plasma science.

Symposium topics

- Plasma physics and techniques

- Vacuum science, techniques and trends

- Protective coatings and thin films

- Characterization of surfaces and thin films

- Thin films for solar cells and sensors

- Plasma based surface treatment technologies

New trends and concepts of plasma based deposition processes Authors of contributions accepted for oral presentation during the Symposium are encouraged to submit their manuscripts to VACUUM.

Young scientists, PhD students and industry engineers involved in PVD technologies are invited to attend the tutorial course offered in the framework of the Society of Vacuum Coaters Educational Program. The full-day course entitled: Application of Reactive Sputtering, covers basics and applications of reactive deposition processes of thin films.

Manufacturers and sales companies offering vacuum equipment, measurement and control systems as well as components for vacuum based science and technology are invited to offer their products and promotion materials during the Industry Exhibition.

Visit the Conference Web Page to learn more: itie.dev.tu.koszalin.pl/svbst2015/index.php

| |

|

|

2015 MRS Fall Meeting & Exhibit

November 29-December 4, 2015

Hynes Convention Center

Boston, Massachusetts USA

The 2015 Materials Research Society Fall Meeting & Exhibit features many new and emerging areas of materials research as well as an exciting mix of well-established and popular topics, including:

- Biomaterials and Soft Materials

- Nanomaterials and Synthesis

- Mechanical Behavior and Failure of Materials

- Electronics and Photonics

- Energy and Sustainability

- Theory, Characterization and Modeling

With 55 technical symposia, more than 6000 oral and poster presentations, an exhibition featuring over 250 international exhibitors from all sectors of the global materials science and engineering communities, and many special events, the 2015 MRS Fall Meeting & Exhibit offers attendees a wide-range of knowledge-building opportunities.

For the most up-to-date information on the 2015 MRS Fall Meeting, visit www.mrs.org/fall2015 regularly.

| |

|

|

Do You Have an Interesting Article to Share?

|

Interested in sharing the latest news in vacuum coating technology? Forward us a link to an article you want to share with the rest of the SVC readership to publications@svc.org. Purchase advertising space in this newsletter by contacting SVC at svcinfo@svc.org.

Society of Vacuum Coaters

71 Pinon Hill Place NE

Albuquerque, New Mexico 87122

505-856-7188

|

|

|

|

|