| |

| In This Edition: |

| >> |

Protective Cover For Diaphragm

Level Switch

(more) |

| >> |

Tech Tip: What maintenance

should be done for the SiloPatrol®?

(more) |

| >> |

Featured Article: Not all

fail-safe rotary paddle point level sensors are created equal

(more) |

| >> |

Employee Profile (more) |

| >> |

Upcoming Shows

(more) |

| Other Information: |

| >> |

Most important factor for improving accuracy

of material weight calculation (more) |

| >> |

Solutions for plugged chute detection (more) |

| >> |

View our entire list of Technical Articles,

White papers and Case Studies

(more) |

Check out www.monitortech.com

for more news. |

| >> |

www.grainnet.com

(more) |

| >> |

Industry News Center

at

www.powderandbulk.com

(more) |

| >> |

Storage Industry Zone at

www.powderbulksolids.com

(more) |

| >> |

Latest News at www.waterandwaste

water.com

(more) |

Very

Interesting...

A Thanksgiving

meal on the moon?

It is said that Neil Armstrong and Edwin "Buzz"

Aldrin's first meal on the moon consisted of roasted

turkey and all of the trimmings in foil food packets.

|

|

|

| |

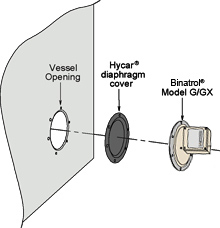

The

Hycar® (rubber nitrile)

optional cover is designed to provide Monitor Technologies'

Binatrol® Model G/GX diaphragm

level switch with additional durability for use with more abrasive

dry materials. The Binatrol diaphragm level switch is a reliable,

low maintenance and cost-effective way to monitor high, low

and intermediate levels of powder and bulk solids in storage

bins, hoppers, silos, and vessels. The diaphragm level switch

can also be used to detect plugged or backed-up conveyor chutes

for some applications.

Figure 1

The Binatrol is a surface mounted, minimally intrusive switch

that makes it ideal for vessels limited in size or internal

clearance. The ability to maintain the unit from outside of

the vessel can be a big asset. All parts are accessible from

outside of the bin, without removing the mounting flange. The Binatrol

is installed to allow its sensing diaphragm to be exposed to the

material being detected.

|

![]() |

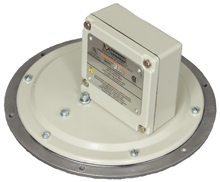

BINATROL® Model

G/GX

Bulk material contacting

the unit transfers force to an internal lever arm assembly,

which than causes the dry contact SPDT 15 Amp switch to be

activated. Common material applications for the Binatrol include

grain, seed, wood chips, sawdust, cement, powders, resins,

pellets and more.

Monitor

offers a variety of diaphragm bin level indicators that can

be configured with various switch sensitivities, diaphragm

materials and approval ratings. Also, Binatrol diaphragm switches

require no input power.

For more information, please visit

http://www.monitortech.com/product_p_diapr.shtml

Or call us in the USA at 800-766-6486 or from anywhere at

630-365-9403. Also, check out our Level

Measurement blog at http://monitortech.typepad.com.

|

|

Happy Holidays!

Everyone at Monitor would

like to wish you and your family a happy and safe holiday

season. Below is a schedule of the days Monitor will be closed

for the upcoming 2010 holidays.

Thanksgiving

Thursday, Nov. 25th

Friday, Nov. 26th |

Christmas

Thursday, Dec. 23th

Friday, Dec. 24th |

New

Year

Thursday, Dec. 30th

Friday, Dec. 31st

|

|

|

Upcoming Shows

(Visit Monitor at the following trade

shows)

|

|

Exchange

2011 Exchange

2011 |

Booth # 926

February 27 - March 1, 2011

Portland Convention Center

Portland, OR USA

www.geaps.com |

|

|

Booth # 10633

March 22 - March 26, 2011

Las Vegas Convention Center

Las Vegas, NV USA

www.conexpoconagg.com |

|

| |

Tech Tip: |

What maintenance

should we perform on the Silo Patrol® cable

based bin level sensors? How often? |

|

|

| |

The

SiloPatrol® cable-based level sensors do

not require a lot of "fussing" with.

Therefore a regularly scheduled maintenance procedure for

these units is not necessary. We do, however, recommend that

the following things be checked and performed as needed before

the cold season:

For the Wiper Seal & Brush

* Ensure cable freely travels through the

entire wiper seal assembly.

* Clean wiper seal and brush as needed (compressed

air or a toothbrush or similar works great) or replace if

excessively worn.

For the Cable

* Ensure there are no kinks, bends, "fish

hooks" and knots on the cable.

* Ensure the jacketing is not fraying or

peeling off the cable. Replace as needed.

For the Rollers

* The white rollers on the cable side of

the SiloPatrol unit should spin in both directions freely.

* The black wheel should spin freely. Ensure that it is tight

on its 'Z' axis. (You can't push the black wheel in and out

a significant distance)

Check the silicone tire in the measurement wheel for cracks or wear. Replace

measurement wheel if worn.

|

|

For the Plumb Bob

* Ensure the plumb bob is clean and securely

attached to the cable.

* Verify that plumb bob attachment hardware

is in good condition.

For more information on the SiloPatrol® cable-based

level sensor,

please visit:

http://www.monitortech.com/product_c_c_sp.shtml

Please visit our blog at . . .

http://monitortech.typepad.com

John Mish

Sales / Technical

Support

|

|

|

|

Featured

Article:

"Not all fail-safe rotary paddle point

level sensors are created equal"

|

SafePoint®

"Truly" Fail-Safe

Level Sensor

|

When

looking for new or replacement point level bin indicators,

you will likely be comparing sensor features from various

equipment manufacturers. Some of these manufacturers

have a model available with a feature that is referred

to as “Fail-Safe”. Other manufacturers might

offer a sensor model depicted to be “Truly Fail-Safe”, “Fail-Safe

Plus”, “Self Validating”, “Genuine

Fail-Safe Protection”, “Advanced Fail-Safe

Protection”, etc. There are definite differences

that should be considered during the sensor selection

process...

For the complete article please visit Powder Bulk

Solids web site at:

http://www.powderbulksolids.com/editorial/detail-article.php?id=4784

For more information on the SafePoint® "true" fail-safe

rotary paddle level sensor please visit:

http://www.monitortech.com/product_p_fails.shtml

|

|

|

|

|

| Name: |

Jeff

Cole |

| DEPT: |

Engineering |

| TITLE: |

Engineering Mgr.

(& head cartoonist) |

| ANIV: |

Nov. 1989 |

|

|

Interview

Q: Where are

you from originally?

A: Plano, Illinois.

Q: What

is your favorite food?

A: What isn't?

Q: Favorite sports team?

A: Chicago Bears.

Q: Hobbies

outside work?

A: Fishing, writing, woodworking, reading.

Q: Favorite

vacation location (Have gone to or would like to go to)?

A: My favorite location that I’ve been to is Alaska.

Q: What consumer item

reminds you most of Monitor?

A: A Plano tackle box of course!

Q: Current

& previous positions you have held

at Monitor?

A: My current position is Engineering Manager. Before that my position

was Mechanical Engineer.

Q: What is the best aspect of

working at Monitor?

A: Lunch and recess! Just kidding. The diversity of the people

that work here.

Q: Current Projects?

A: I have

been working on the next cartoon

for our upcoming magazine

ads.

|

|

|

|

|

| |

|

|

|