Capital Argument$

A trademark of Paperitalo Publications

|

|

|

Published on the 15th of every month

|

|

|

|

|

|

|

|

How to approach an expansion/upgrade Project

Part 3--Raw Materials

The second most critical item, as we continue this series, is raw materials. And just to make sure we don't forget it, we'll include fuels in raw materials. This may leave you scratching your head, but if you work in a virgin fiber mill, the bark boiler is an energy generator dependent on your primary raw material stream for its calories.

Virgin raw material streams are usually easier to predict than recycled streams, although in the last 25 years, we have gotten a lot smarter about the dynamics of the recycled market. Trees don't move, and barring a major natural disaster, one likely to leave you worried about a lot more than just your fiber source (think Mount St. Helens), their availability should be fairly stable and predictable.

One other problem with virgin raw materials has recently (last 10 years) popped up in the southern US. Chip mills, which are chipping trees for burning in European power plants. The trees did not move to a new market, but a new market moved to the trees.

Recycled fiber, on the other hand, is subject to vagaries of supply and demand and pressures from markets far from where your mill is located. You have less control over a fiber supply that can move versus one that stays rooted near your mill, so to speak.

The financial community, by the way, calls a recycled mill a "tolling facility." This comes from toll roads. For what is really happening is you are running fiber in one end of the mill, doing some things to it to make it more valuable, and disgorging it at the other end to your customers. A toll road, similarly, accepts vehicles at one end of a communication device (the highway) and adds value by disgorging them safely at the other end. Same thing. Profit is made based on the size of the tolls and the efficiency of the operation and maintenance team (same thing again).

Locking up your energy sources is just as important as locking up your raw materials (fiber) sources. Further, these days, you have to take into account the regulatory environment--what if you built a mill that depends on cheap coal for energy and suddenly wake up to find the government's objective is to ban the burning of coal long term?

The engineers can have input to these matters, but you better have some other experts around who really know their stuff when it comes to raw materials and the dynamics of the raw materials markets.

Engineering Manager of the Year, call for nominations

We are looking for an individual who has done an extraordinary project, one that almost defies belief. Its extraordinary features can be schedule, technology, cost or all three.

We have often gotten nominees that go something like this, "I nominate Joe because he has done a great job of running our engineering department for the last fifteen years." Quite frankly, we are not interested in such nominees.

However, if you know someone who has led a very exceptional project in the recent past (the last two or three years), we want to know about it. We want to honor them and hold them up as an example for Engineering Managers in every pulp and paper mill around the world.

Just send your nomination, with as much details as you can provide, to jthompson@taii.com. We will seriously consider it.

|

________

Current Patent Activity is available here.

|

|

________

Capital Arguments Engineering Manager of the Year

Hall of Fame

Since its inception, Capital Arguments has believed extraordinary projects are possible. They can be done safely, responsibly and offer a great advantage to their mills with lower capital costs and saved downtime. We established this award in 2008 to recognize those people and companies that follow this philosophy. This award is given once per year somewhere in the world. We honor our inductees permanently here. Since its inception, Capital Arguments has believed extraordinary projects are possible. They can be done safely, responsibly and offer a great advantage to their mills with lower capital costs and saved downtime. We established this award in 2008 to recognize those people and companies that follow this philosophy. This award is given once per year somewhere in the world. We honor our inductees permanently here.________

Ed Kersey--Engineering Manager of the Year 2011

Jim presents Ed with the Engineering Manager of the Year for 2011. (L - R) Matt Nilsen, Jim Thompson, Ed Kersey and Wayne South. Nilsen is Account Manager and South is Business Development Manager for Kadant Black Clawson, underwriter of this year's award. Ed Managed the construction of the Pratt Industries mill in Shreveport, Louisiana which took 13 months from piling to paper on the reel. His reward? They made him mill manager!

Kadant Black Clawson was a major sponsor of the 2011 Award. Here, on the left, Peter Flynn, President of Kadant Black Clawson, receives the company's duplicate of Ed's Award from Steve Roush, Publisher and Editor, Paperitalo Publications.

________

Not Awarded 2010You have to be really good to get this award. We did not receive any qualifying nominations in 2010.________

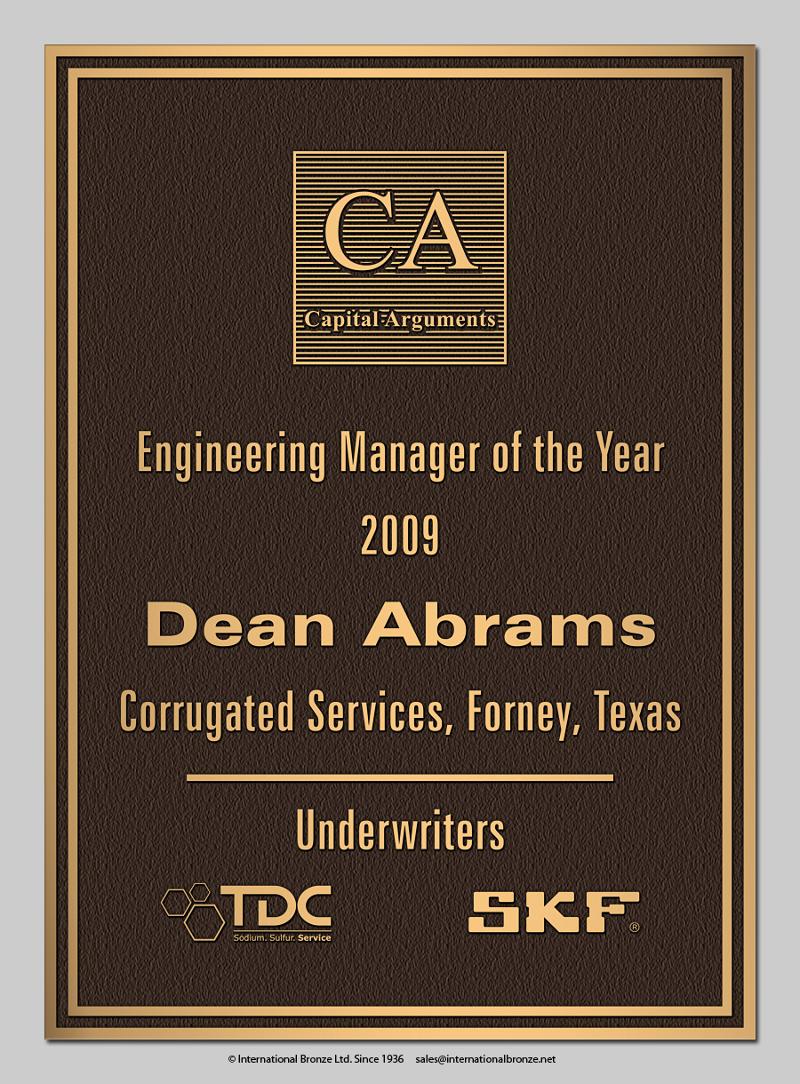

Dean Abrams--Engineering Manager of the Year 2009

Now retired, Dean was an engineer at Corrugated Services, Forney, Texas, USA in the summer of 2009 when he completed his award winning project. Dean managed a team that installed a secondary headbox in 11 hours, 30 minutes, paper-to-paper. The experts had said it would take at least 3 days. In April 2010, we presented the award to Dean in the presence of a number of his colleagues.

Here is the award we presented to Dean:

Mike Ahcan--Engineering Manager of the Year 2008

Mike works at the UPM Blandin Mill in Grand Rapids, Minnesota, USA. In 2008, the mill's sole effluent pipe, running outside a building, almost in the Mississippi River, was determined to be in a state of imminent collapse. The experts said it would take a week of total mill downtime to replace it. Additionally, there was a danger of leakage into the river. Mike and his team went to work and replaced the pipe without any downtime and with no spillage. We had a banquet in Grand Rapids for him in July 2009.

And here is Mike's award:

We normally accept nominations in the November-December time frame. They can be sent to jthompson@taii.com with "EMOY Nomination" in the subject line.

|

|

|

|

|

________

Please write when we tickle your brain cells! Email jthompson@taii.com

|

|

|

________

|

|

|

|

|

|

|