The beginning of the rainy season in Costa Rica is September 1st. While most resorts furlough their employees, at Nosara Paradise Rentals and FishingNosara we keep our full staff together for two months of intensive maintenance and expansion of our boats, vehicles, safari carts, and properties.

In this special edition of the Costa Rica Fishing Report, we will take a behind-the-scenes look at the projects and people that will make 2012 our best year to date.

The Wanderer will be entering her third year of service (man, time flies! It seems like yesterday we sent the Wanderer to Nosara) and she was ready for a major refit. An every-day boat like this demands lots of annual upkeep, and this season put a few new scars in the blue beauty that would take Craig Sutton Jr.'s expertise to repair.

In late August, the Wanderer was damaged when she was engulfed by a rouge wave at her mooring point in Garza Bay. As the 31-foot craft bucked in the waves, the entire weight of the boat clung to the rope through the steel pulpit on the nose.

Here is what Craig was looking at upon his arrival on September 1:

The first step was to prepare the work area with a makeshift tent to keep the exposed fiberglass dry; this ensures that the new fiberglass resin will set up and harden without trapping any air bubbles or wood-rotting moisture.

Once Captain William and First Mate Alex completed the rain guard, Craig and Matty got down to the dirty work of sanding/grinding the damaged material.

Now it's time for some fiberglass. Because of the huge industries of boating and surfing, the quality of fiberglass resin and hardener in Costa Rica is actually better than what we get in the USA; it has less impurities, sets up faster and sands cleaner.

Notice how Craig puts a wad of material as deep in the hole as possible; this works in conjunction with the layers inside the anchor box to create a pure fiberglass plug that is form-fit to the hole.

After the first day of fiberglass, the nose of the Wanderer was watertight once again.

However a few more coats of resin and a lot of fine sanding would still be required to bring this area back to pre-damage conditions.

Notice how the deck line is still not quite straight (see right); we let the repair cure and dry before coming back a few days later to sand, add more fiberglass, and put the finishing layer on.

Craig and Matty were back at it on September 7 for the final touches. By using a flat edge of cardboard rather than a paintbrush, Craig was able to create a near-perfect flat surface for the final layer.

One more late night of sanding, and Craig stepped away from this repair confident that the nose of the Wanderer is stronger than before and the surface under the pulpit is as smooth and level as a dance floor.

Of course it is easier to have a professional do your fiberglass work (or any boat work for that matter), but the quality and attention to detail that comes from working on your own boat can not be understated.

Take for example the passageway to the forward observation deck. The Wanderer's clients have grown to love this panoramic view of the Pacific for photography and the easy access to sunbathing on the prow.

These photos (right, below) were taken in November 2009 when this boat was fresh as a daisy.

Unfortunately this porthole has taken a beating over the last two years and the bolt hinge got completely stripped.

While waiting on fiberglass to dry, Craig tracked down a tap-and-die set and cut a fresh hole for the hinge bolt. This repair, while small in scale and expense, is an example of the attention to detail required to keep a 31-foot boat running in Costa Rica.

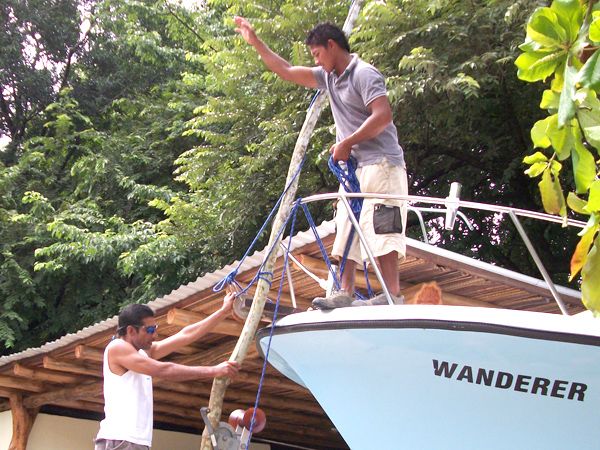

The final step to get the Wanderer ready for many more years of bad to the bone billfishing was to tighten the canopy top and freshen the 5200 Marine silicon that keeps the sea spray out of the cabin.

After lifting the roof and supporting it was some trees we found laying around ("Costa Rican jackstands" Matty called them), we applied fresh 5200 and 3.5 inch new stainless screws to replace the 20+ year old, 2.5 inch fasteners.

The increase in strength all-around is obvious, ensuring many more years of service from the rugged Wanderer. Craig and Matty left Nosara on September 10, and currently Captain William and Alex are servicing the rub rail and re-painting the interior and bottom.

From the nose to the propellers and the bottom paint to the roof, the big blue beauty will be all fixed up and ready for action come November 1.