Miapoxy Website

|

Visit our DIY/Hobbyist website for access to info and immediate ordering capabilities on dozens of our most common products. Visit our DIY/Hobbyist website for access to info and immediate ordering capabilities on dozens of our most common products. |

Request A Quote

|

Use our online quote system and complete pricing and availability information for our thousands of products is just a few clicks away. Use our online quote system and complete pricing and availability information for our thousands of products is just a few clicks away. |

Members Only

|

For our larger industrial customers, we offer our exclusive extranet. For our larger industrial customers, we offer our exclusive extranet.

Read more |

| Closeouts |

Looking for a bargain? Check out our latest

Closeout List.

|

| Videos for Phones | iphone icon  | All of our instructional videos are available in .mp4 format, which is compatible with iPods, iPads, iPhones, & most other smartphones

Download them here.

|

| Archives |

Access past issues of our newsletter.

Check it out.

|

|

|

Greetings!

Welcome to the October issue of Freeman's E-Newsletter!

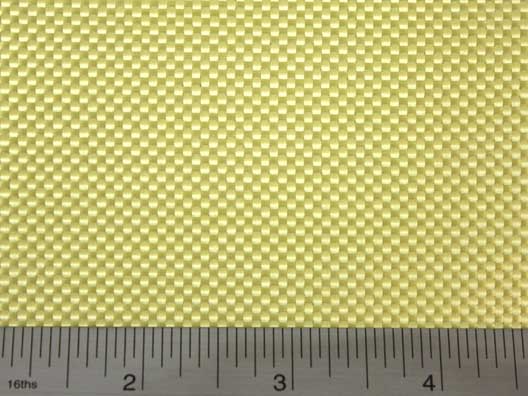

Freeman is now stocking Kevlar fabrics in both the US and Canada.

We have done a bit of housekeeping on our website. Our biggest changes are in the Hardware & Equipment and the Accessories sections, both of which are easier to follow. Much more content is on the way as we put the finishing touches on our (long overdue) catalog.

Our next series of videos is still in pre-production. As always, you'll hear about all new video releases through our newsletter first. Stay tuned.

|

| New Kevlar Fabrics |

|  Freeman now carries three styles of KevlarŪ fabrics, a light 1.7 oz cloth and two 5 oz cloths (plain and 4HS weave). They are stocked in both the US and Canada and available on our Miapoxy website. Freeman now carries three styles of KevlarŪ fabrics, a light 1.7 oz cloth and two 5 oz cloths (plain and 4HS weave). They are stocked in both the US and Canada and available on our Miapoxy website.

|

New Bagging Prices

|

|  We now have quantity discounts set up for our popular Mia vacuum bagging materials and tapes. We now have quantity discounts set up for our popular Mia vacuum bagging materials and tapes.

|

| Exclusive Videos

|

|

As a subscriber, you have access to videos that aren't available anywhere else online. In fact, many new videos will be posted here before they are available via DVD. Just follow the links below. As a subscriber, you have access to videos that aren't available anywhere else online. In fact, many new videos will be posted here before they are available via DVD. Just follow the links below.

Available Now:

In Development: - An expansion of our Vacuum Bagging videos (separating basic & advanced applications)

- Vacuum Infusion Applications

- Composite Repair

|

| Tech-Line Q & A | |  In every issue, we bring you the answers to real-world technical questions that have broad applications. Our technical support staff is available during normal business hours, Monday through Friday, by calling 800-321-8511 (Option 5) In every issue, we bring you the answers to real-world technical questions that have broad applications. Our technical support staff is available during normal business hours, Monday through Friday, by calling 800-321-8511 (Option 5)

Is the Renshape 5169 a suitable material to make female molds for producing fiberglass/carbon fiber parts? We were looking for a substitute for aluminum. This would be for very low volume/prototyping use so the molds would not be required to produce large numbers of parts say 50 or less. Also, this would be for hand layups using epoxy so no pre-preg or high pressure, high heat applications. If there is a Renshape product specifically for this purpose please let me know.

Both RenShape 5169 and RenShape 5179 would be suitable materials for this application.

I have been using the Freeman 1060 Urethane and the V-340 Silicone, and have developed air bubbles in the molds and final product. Do I need to degas these products before they are used? If so how much vacuum is needed to fully degas them.

While not necessary in all applications, both products should be degassed to rid of any air bubbles introduced during mixing. You should be pulling a vacuum of 29 inches of Hg during your degassing process.

What is the temperature rating on Fiberglass Cloth?

Glass fabrics have excellent heat resistance with a softening point of 1,555°F(846°C), and a melting point of 2,075°F (1,121°C).

Is it necessary to use polyvinyl alcohol (PVA) in addition to wax?

The answer to this question depends on a number of factors, but the bottom line is this: if you do not want the part to stick to and possibly ruin your mold, then use PVA. If mold is new or reconditioned, then you should definitely use a PVA such as PartallŪ Coverall Film or PartallŪ Film #10 to prevent styrene migration. If the mold is seasoned, then the use of PVA is not necessary except as additional insurance against sticking as long as wax is applied properly and with sufficient frequency. If the mold is very large or intricate, you may have difficulty achieving adequate cover using wax only. PVA can be sprayed into hard-to-reach crevices and forms a visible barrier that you can see on the mold surface.

What repair and build up material can we use on the RenShape 5008?

We would recommend using our Hi-Temp Tuf-Fil Polyester repair and build-up material.

|

|

We have thousands of technical documents online, including TDS, MSDS and more. We have thousands of technical documents online, including TDS, MSDS and more.

You also have access to the best technical support staff in the industry. Contact Us Today.

|

|

Thank you for subscribing to our newsletter. We look forward to the next opportunity to service your material needs.

Sincerely,

Freeman Manufacturing & Supply Company

|

|

|