Miapoxy Website

|

Visit our DIY/Hobbyist website for access to info and immediate ordering capabilities on dozens of our most common products. Visit our DIY/Hobbyist website for access to info and immediate ordering capabilities on dozens of our most common products. |

Request A Quote

|

Use our online quote system and complete pricing and availability information for our thousands of products is just a few clicks away. Use our online quote system and complete pricing and availability information for our thousands of products is just a few clicks away. |

Members Only

|

For our larger industrial customers, we offer our exclusive extranet. For our larger industrial customers, we offer our exclusive extranet.

Read more |

| Closeouts |

Looking for a bargain? Check out our latest

Closeout List.

|

| Videos for Phones | iphone icon  | All of our instructional videos are available in .mp4 format, which is compatible with iPods, iPads, iPhones, & most other smartphones

Download them here.

|

| Archives |

Access past issues of our newsletter.

Check it out.

|

|

|

Greetings!

Welcome to the June issue of Freeman's E-Newsletter!

We have just released our second new video in as many months! We are now entering pre-production for our next series of videos, which will be shot this summer. For those videos, we'll be focusing on expanding our composite construction and repair section.

As always, you'll hear about all new video releases through our newsletter first. Stay tuned. And make sure to check out our fiberglass special at the bottom.

|

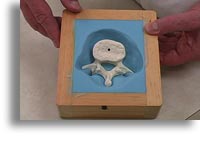

| Another New Moldmaking Video

|

|

ipod icon  | Silicone Rubber Molds with Complex Parting Lines

In addition to last month's announcement of our new video, Casting Molds & Models With Intricate Detail, we are pleased to release yet another moldmaking video. This one, entitled Silicone Rubber Molds with Complex Parting Lines takes you through the process of forming a non-linear (or, non-planar) parting line with modeling clay.

This video also shows how trial and error can play a role in creating an adequate venting system for a complex mold as we initially had voids in our casting which we had to remedy using a couple of handy techniques.

|

A Million Views on YouTube

|

|

fiberglass  | Please allow us a quick moment to toot our own horn. Freeman's YouTube Channel, which is primarily a mirror of our website video library (well, just part of it, really), just reached a million views! So to all of those who have found us through YouTube, thanks and welcome. We hope you stick around.

Note: visits to our freemansupply.com video library don't count as YouTube views since we don't use the YouTube links on our own website (as many other sites do). We still do it "old school" - both Windows and Quicktime formatted videos, hosted on our own servers. We just think the quality is a lot better for the bandwidth.

|

| Exclusive Videos

|

|

As a subscriber, you have access to videos that aren't available anywhere else online. In fact, many new videos will be posted here before they are available via DVD. Just follow the links below. As a subscriber, you have access to videos that aren't available anywhere else online. In fact, many new videos will be posted here before they are available via DVD. Just follow the links below.

Available Now:

In Development: - An expansion of our Vacuum Bagging videos (separating basic & advanced applications)

- Vacuum Infusion Applications

- Composite Repair

|

| Tech-Line Q & A | |  In every issue, we bring you the answers to real-world technical questions that have broad applications. Our technical support staff is available during normal business hours, Monday through Friday, by calling 800-321-8511 (Option 5) In every issue, we bring you the answers to real-world technical questions that have broad applications. Our technical support staff is available during normal business hours, Monday through Friday, by calling 800-321-8511 (Option 5)

I am creating a prototype using Repro Light. I plan to pour 8 pieces 1/8" Thick x 4" Long. Could you tell me if it would be as rigid as, as strong as, or stronger than using poplar wood.

How would the other properties of my silicone rubber be affected by adding the Bluestar 47V-50 silicone fluid?

Hardness, tensile strength, tear strength, and density will all decrease. Elongation will increase slightly. The cure time will also increase.

What can I use to adhere Renshape to my pattern plate (Aluminum/Dowmetal)?

There are various methods you can use to adhere a piece of RenShape to your pattern plate. Doweling can be used to align your pattern. Spot gluing can be done with our Fast Set 505, or mechanically with the use of helicoils.

We are looking for a metal filler that is easy to sand and that will withstand 400°F as it must cure in an oven after it has been powder coated.

We would suggest taking a look a the Alvin Hi-Temp Lab Metal. The Hi-Temp Lab Metal can withstand temperatures up to 1,000°F and works well in powder coating applications.

What is a good material for a fast yet durable repair to an aluminum mold that will be subjected to elevated temperatures?

Freeman Hi-Temp Tuf-fil is an excellent repair material for this application. It has a paste consistency, is inexpensive, and solidifies in 15 minutes. Plus, it can be sanded or machined to the contour of the part, providing a durable, long lasting repair that can withstand temperatures of 350ºF.

|

|

We have thousands of technical documents online, including TDS, MSDS and more. We have thousands of technical documents online, including TDS, MSDS and more.

You also have access to the best technical support staff in the industry. Contact Us Today.

|

|

Thank you for subscribing to our newsletter. We look forward to the next opportunity to service your material needs.

Sincerely,

Freeman Manufacturing & Supply Company

|

|

|