Miapoxy Website

|

Visit our DIY/Hobbyist website for access to info and immediate ordering capabilities on dozens of our most common products. Visit our DIY/Hobbyist website for access to info and immediate ordering capabilities on dozens of our most common products. |

Request A Quote

|

Use our online quote system and complete pricing and availability information for our thousands of products is just a few clicks away. Use our online quote system and complete pricing and availability information for our thousands of products is just a few clicks away. |

Members Only

|

For our larger industrial customers, we offer our exclusive extranet. For our larger industrial customers, we offer our exclusive extranet.

Read more |

| Closeouts |

Looking for a bargain? Check out our latest

Closeout List.

|

| Archives |

Access past issues of our newsletter.

Check it out.

|

|

|

Greetings!

Welcome to the March issue of Freeman's E-Newsletter!

In addition to the product announcement and new newsletter feature below, we have been working on a number of other enhancements, including updated selection guides and expanded product offerings, which we will announce here when they are ready.

|

| Product Announcement |

|

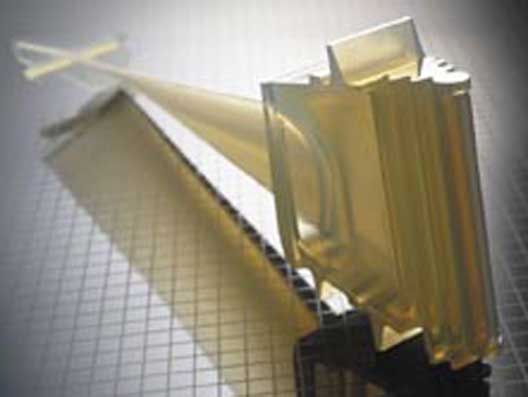

Freeman has officially entered the SL market!! Freeman has officially entered the SL market!!

Due to an exclusive arrangement with Huntsman Advanced

Materials, Freeman is now offering RenShape V1 and RenShape V2

Stereolithography resins for use on Solid State Laser SLAŽ Systems.

Both of these

products offer an outstanding blend of price and performance. These resins, without sacrificing

quality, are very well priced for today's highly competitive marketplace.

RenShape V1 is an excellent choice for generating QuickCast™ build style patterns while RenShape V2 is ideal for creating

parts that mimic Polypropylene. Call us at 800-321-8511 Ext 773 to learn more

about these exciting new products and how they might enhance your prototyping

business.

|

| New Newsletter Feature |

|

Access Our Archives!! Access Our Archives!!

Freeman has set up a special web page for our newsletter subscribers to access prior newsletters, including past announcements and, more importantly, technical Q & A.

|

| Exclusive Videos

|

|

As a subscriber, you have access to videos that aren't available anywhere else online. In fact, many new videos will be posted here before they are available via DVD. Just follow the links below. As a subscriber, you have access to videos that aren't available anywhere else online. In fact, many new videos will be posted here before they are available via DVD. Just follow the links below.

Available Now:

Coming Soon:

- Casting Molds & Models With Intricate Detail

- Silicone Rubber Molds with Complex Parting Lines

In Development: - Update to Basic & Advanced Vacuum Bagging Applications

- Vacuum Infusion Application

|

| Tech-Line Q & A |

|

In every issue, we bring you the answers to real-world technical questions that have broad applications. Our technical support staff is available during normal business hours, Monday through Friday, by calling 800-321-8511 (Option 5) In every issue, we bring you the answers to real-world technical questions that have broad applications. Our technical support staff is available during normal business hours, Monday through Friday, by calling 800-321-8511 (Option 5)

What can I use to thin the viscosity of my silicone rubber?

The 47V-50 Silicone Fluid is used to reduce the viscosity of the two-part silicone rubber. Add 5-10 parts by weight (10 is the maximum recommended) of the 47V-50 to 100 parts of silicone base (part A).

How can I increase the strength of the RTV silicone rubber?

The most commonly used method for increasing the physical strength of the silicone RTV materials is by adding 2.0-4.0 parts by weight (pbw) of fumed silica filler. However, doing so may thicken the material and require mixing special equipment to thoroughly disperse the additive.

What is the proper procedure to release epoxies/ urethanes from a porous pattern/ mold?

1. Make sure your mold is properly sealed.

a. Apply one coat of Freeman Wood & Plaster Sealer to the bare wood surface using a pure bristle brush and allow the material to absorb into the wood. b. After the first coast has dried (approximately half an hour), you will notice that the sealer has swelled the grain and made it rough. Use sand paper or Scotch-BriteŽ, lightly sand the surface to make it smooth again. Sanding is not necessary when working with plaster or sheet wax. c. Wipe off the pattern with a cloth and then apply a second coat of sealer d. After allowing the second coat to dry (preferably overnight), lightly sand the wood again and wipe it off with a cloth. e. You are now ready to apply the release agents. 2. Brush on a layer of Freeman Wax Release3. Allow coat to dry or immediately wipe off the excess with a cloth 4. We suggest at least two coats of Wax Release to make sure your entire part is covered evenly. 5. Next, you will need to apply two layers of Partall PVA Mold Release. 6. Each coat will require a half hour of drying time unless you use a fan or air hose. 7. After the second coat of PVA has dried thoroughly, apply a final coat of Freeman Wax Release. 8. Buff this last coat gently so as not to break through the layers of the PVA.

Customers have had success with the above procedure, but it is always a good idea to test before using any type of release procedure before proceeding with project.

Can I use lumber or plywood to make a core in a cast epoxy/ polyurethane thermoform tool so I don't have to use so much resin?

This is not a good idea. The wood core and the epoxy or polyurethane resin will expand and contract at different rates as the tool heats and cools. This will introduce stress into the tool during cycling. This could cause cracking that would require repair or replacement of the tool.

Additionally, lumber cores will dry out as they are heated during production runs. This drying out will lead to cracking, checking, and warping of the wood core. This will also introduce stress and most likely cause the tool to warp or crack. It is always good practice to cast a tool out of solid resin. If tool size makes this impractical, then reconsider the tool construction technique. Perhaps the tool should be made using fiberglass and laminating epoxy.

| |

We have thousands of technical documents online, including TDS, MSDS and more. We have thousands of technical documents online, including TDS, MSDS and more.

You also have access to the best technical support staff in the industry. Contact Us Today.

|

|

Thank you for subscribing to our newsletter. We look forward to the next opportunity to service your material needs.

Sincerely,

Freeman Manufacturing & Supply Company

|

|

|